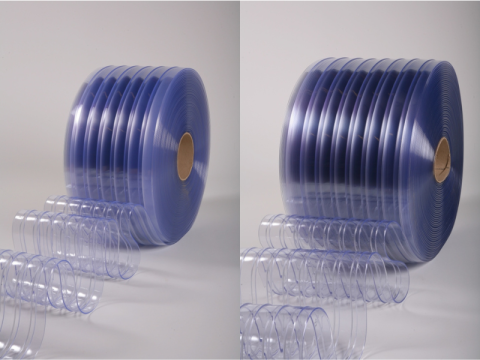

Discover how Extruflex ribbed PVC strips deliver unmatched durability and efficiency for industrial and commercial applications.

In today’s industrial environments, where efficiency and durability are critical, choosing the right materials is key to smooth operations and long-term success.

At Extruflex, we don’t just create PVC strips—we engineer solutions that meet the real-world demands of busy industrial environments, delivering unparalleled durability and efficiency. Ribbed PVC strips are a prime example of this commitment. Engineered to endure the rigours of high-traffic settings, they offer unmatched longevity and reliability across a wide range of applications.

With their robust ribbed design and exceptional resilience, ribbed PVC Strips are more than just durable—they set a new standard for industrial materials, ensuring your operations remain efficient and seamless even in the toughest conditions.

How do ribbed PVC strips redefine durability?

Ribbed PVC Strips are not your average flexible PVC strip solution. They are meticulously engineered to handle the toughest conditions while maintaining peak performance. Their unique ribbed design significantly enhances durability, making them a standout choice in challenging environments.

Key features that make a difference:

- Premium Material Composition: Manufactured from high-grade PVC, these strips are designed to resist cracking and tearing, even with frequent use in demanding settings.

- Ribbed Reinforcement: The ribbed design reduces friction and wear, extending the lifespan of the strips in high-traffic areas.

- Impact Resistance: Engineered to absorb frequent impacts without compromising structural integrity.

- Clarity and Visibility: Maintains high transparency for improved safety and efficiency in busy workspaces.

- Thermal Insulation: Acts as an effective barrier to maintain consistent temperature zones and lower energy costs.

- Temperature Resilience: Performs dependably in extreme conditions, from freezing to warm environments, without losing flexibility.

- Non-Adhesive Surface: Ensures smooth operation by preventing sticking and prolonging product life.

- Eco-Friendly: Fully recyclable and free from harmful phthalates, supporting sustainability initiatives.

Applications of ribbed PVC strips

Industries that operate in challenging conditions trust Extruflex ribbed PVC strips for their ability to withstand constant use while maintaining their effectiveness. Here’s how they are used:

Key use cases:

- Warehousing and Logistics: Withstand constant forklift and pedestrian traffic, while also acting as an efficient thermal barrier, helping to reduce energy costs.

- Food Processing Plants: Maintain hygiene standards with chemical-resistant and easy-to-clean surfaces.

- Cold Storage Facilities: Perform reliably in extreme temperatures, ensuring consistent insulation and energy efficiency.

- Retail and Supermarkets: Provide clear, durable partitions for seamless movement and long-lasting performance.

- Manufacturing Facilities: Separate production areas efficiently while withstanding heavy equipment traffic and industrial processes.

- Pharmaceutical Environments: Ensure clean, temperature-controlled spaces while maintaining transparency and hygiene compliance.

- Airports and Transportation Hubs: Facilitate smooth passenger and equipment flow with clear, robust partitions for high-traffic areas.

- Data centres: Maintain controlled temperatures for sensitive equipment in data centres while allowing easy access with durable strip barriers.

Why do businesses choose Extruflex ribbed PVC strips?

Businesses across industries choose Extruflex ribbed PVC strips because they deliver tangible benefits that enhance operational efficiency, reduce costs, and provide long-lasting performance.

Here’s what sets them apart:

- Exceptional Durability: The ribbed PVC Strips' ability to withstand constant traffic without wear and tear helps businesses save on maintenance costs, ultimately contributing to bottom-line savings.

- Cost-Effective: Their long lifespan reduces the need for frequent replacements, offering significant savings over time.

- Energy Efficiency: With outstanding thermal insulation, they help maintain temperature zones, reducing energy consumption in temperature-sensitive operations.

- Safety and Compliance: High visibility and non-stick surfaces improve workplace safety and meet industry hygiene standards.

- Versatility: Suitable for a wide range of applications, from industrial warehouses to cold storage facilities and retail spaces.

- Sustainability: Manufactured with recyclable materials, they align with modern environmental goals, making them a responsible choice for businesses.

When businesses need a solution they can rely on, they turn to Extruflex.

Our ribbed PVC strips are designed not only to meet industry challenges but to exceed expectations, providing the perfect combination of durability, performance, and value.

Why trust Extruflex?

Extruflex is at the forefront of PVC solutions, combining innovation, quality, and sustainability to meet the needs of modern industries.

With over 60 years of industry expertise, Extruflex has helped businesses improve operations with cutting-edge solutions like our ribbed PVC strips, known for their precision engineering and longevity.

Ribbed PVC strips are a testament to our commitment to excellence. Designed and manufactured with precision, these strips reflect our dedication to delivering solutions that prioritise durability, efficiency, and environmental responsibility.

When you choose Extruflex, you’re not just choosing a product—you’re partnering with a brand that understands the challenges of your industry and works to solve them.

Frequently asked questions (FAQ) about ribbed PVC strips

- What makes Extruflex ribbed PVC strips more durable than regular PVC?

- The ribbed design minimises friction and reduces surface contact, preventing wear and extending lifespan.

- Can ribbed PVC Strips handle extreme conditions?

- Yes, they are designed to perform under high-impact, high-traffic, and temperature-controlled settings.

- Are these strips eco-friendly?

- Absolutely. They are 100% recyclable and free from harmful phthalates.

- Which industries benefit most from ribbed PVC Strips?

- Warehousing, logistics, food processing, cold storage, and retail environments benefit greatly due to their durability and versatility.

- How do these strips help reduce energy costs?

- Their superior thermal insulation properties maintain temperature zones effectively, reducing energy consumption.

- What are common applications for ribbed PVC Strips?

- They are ideal for strip curtains, swing doors, and partitions where durability and insulation are critical.

Contact Extruflex for reliable, durable PVC solutions

At Extruflex, we understand that durability is non-negotiable in industrial environments. That’s why our ribbed PVC strips are designed to deliver superior performance, enhance efficiency, and reduce costs. From energy savings to long-term reliability, this product is an investment in operational excellence.

Contact us today to learn more about how Extruflex ribbed PVC strips can transform your operations, or explore our full range of innovative PVC solutions on our website. Together, we can build a more efficient, durable future.