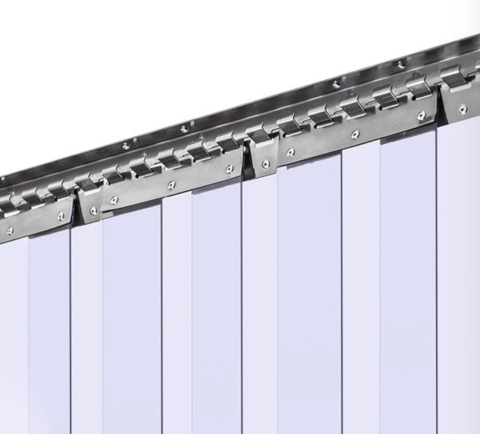

Discover why the Hook on Track & Plate System is trusted worldwide for PVC strip curtain installations.

PVC strip curtain systems are only as reliable as the hardware supporting them. The mounting hardware—often treated as an afterthought—plays a vital role in ensuring reliable operation over time.

The Hook on Track & Plate System addresses this need with a straightforward approach – easy installation, secure suspension, and simple maintenance. Its popularity across warehouses, food plants, and cold storage facilities has earned its reputation by holding up in real-world conditions—where equipment is judged by how well it works, not how it’s promoted.

1. Ease of Installation

The Hook-on Track & Plate System is designed for simplicity and versatility. Whether you're installing a complete strip curtain system or sourcing components separately, it offers a practical, high-performance solution.

Each flexible PVC strip can be pre-fitted with a reinforced stainless-steel plate featuring pre-punched holes. These hook directly onto the track, eliminating the need for clamps, bolts, or specialist tools — making installation clean, fast, and efficient.

We offer a variety of plate and rail options, all fully compatible with the Hook-on system:

- Curved 201-grade stainless steel in polished and non-polished finishes

- Flat plate available in polished finish only

- Heavy-duty Hook-on rails with deeper profiles and an additional top plate, available in polished finish only — ideal for larger or heavier curtains

All hardware is manufactured from 201-grade stainless steel, offering superior strength and durability compared to lower-grade alternatives like 430 stainless. For customers purchasing pre-cut strips, the system is ready to install out of the box. For those buying PVC rolls in bulk, hardware is available separately — sold individually or by the box — giving you full control over finish and configuration.

2. Long-Term Durability

PVC strip curtain systems are often exposed to conditions that test the limits of their hardware—fluctuating temperatures, constant moisture, and continuous mechanical stress. The Hook on Track & Plate System is built for demanding settings where lesser hardware breaks down.

Corrosion-resistant materials

Each track and plate component is manufactured from AISI 201 stainless steel, offering high resistance to rust and degradation. This makes the system especially well-suited for chilled storage areas, washdown zones, and other moisture-prone environments where lesser materials would deteriorate quickly.

Secure, stable mounting

The hook-on design not only simplifies installation but also ensures a mechanically strong connection. Strips remain firmly in place—even with repeated contact from pallet trucks, forklifts, or strong air currents—maintaining their alignment and effectiveness over time.

Minimal maintenance demands

By relying on high-grade stainless steel, the system reduces the likelihood of corrosion-related failures. That translates into fewer repairs, longer intervals between replacements, and more predictable performance, even in hygiene-sensitive environments like food processing or pharmaceutical facilities.

With its robust construction and low upkeep requirements, the Hook on Track & Plate System is built for places where stopping production just isn’t an option—like food plants, pharma labs, or 24/7 logistics hubs.

3. Maintenance & Replacement Efficiency

PVC strip curtains are exposed to continuous wear, especially in high-traffic zones. Over time, individual strips may degrade and require replacement to maintain visibility, hygiene, and safety. The Hook on Track & Plate System is designed with this inevitability in mind.

Targeted strip replacement

Worn or damaged strips can be replaced individually—there’s no need to remove the full curtain assembly or disassemble the track. This modularity makes upkeep more manageable, allowing maintenance teams to address issues as they arise without interrupting wider operations.

Tool-free access

Thanks to the hook-on design, no tools are required to remove or rehang strips. In-house teams can carry out replacements quickly and safely, reducing reliance on specialist labor and keeping maintenance overheads low.

Low-disruption workflow

The ability to replace strips in place—without halting nearby operations—is particularly valuable in environments where temperature control, cleanliness, or uninterrupted access is essential. Whether in cold chain logistics, clean zones, or production areas, the system enables swift, localized updates with minimal disruption.

This design supports both routine maintenance and rapid response to damage, helping teams meet tight timelines and stay compliant with health and safety rules.

Top 5 Industries That Rely on the Hook on Track & Plate System

The Hook on Track & Plate System is trusted across a wide range of sectors for its balance of durability, hygiene, and ease of use. Its adaptable design makes it suitable for both heavy-duty industrial environments and highly controlled settings where precision matters.

1. Cold Storage and Refrigeration

In temperature-sensitive environments, reliable hardware is non-negotiable. The stainless steel construction of the Hook on Track & Plate System resists corrosion caused by condensation and maintains structural integrity even in sub-zero conditions, ensuring continuous performance where insulation and containment are critical.

2. Food Processing and Packaging

Maintaining hygiene standards is central to food production environments. The system’s smooth, stainless steel surfaces are easy to sanitize and compliant with industry regulations, allowing for clean zoning of workspaces without compromising ease of access or operational flow.

3. Warehousing and Logistics

Facilities that handle constant vehicle movement demand systems that can hold up under pressure. This hardware is built to endure repeated contact from forklifts and trolleys, keeping strip curtains securely in place across high-traffic loading bays and internal partitions.

4. Manufacturing and Assembly Lines

In production facilities, clear sightlines and safe separation are essential. The Hook on Track & Plate System enables fast installation of strip curtains that divide workstations, manage dust, and reduce noise—without hindering efficiency on the floor.

5. Clean Rooms and Controlled Environments

When environmental control is paramount, even minor air exchanges can compromise performance. This system keeps curtains aligned and gaps sealed—critical in labs, pharma areas, or cleanrooms where even a small draft can cause problems.

Upgrade Your Mounting Hardware

In environments where operational efficiency, hygiene, and durability are non-negotiable, the Hook on Track & Plate System consistently delivers. Its tool-free maintenance, robust stainless steel construction, and flexible modular design make it not just another mounting bracket. It’s a system that saves you time, holds up under pressure, and simplifies daily maintenance. From sealing off cold rooms to helping meet hygiene codes, it does the job without compromise.

To find out how the Hook on Track & Plate System can be integrated into your facility, contact the Extruflex team or request a tailored quote today.