From quick-install systems to heavy-duty mounts, Extruflex offers tailored mounting hardware solutions that maximize performance, durability, and ease of use.

The right hardware is the backbone of any effective PVC strip curtain system. Without durable and well-designed mounting solutions, even the best strip curtains can underperform, leading to inefficiencies and increased operational costs.

Choosing the right components ensures a secure fit, seamless operation, and hassle-free maintenance while extending the lifespan of strip curtains. Proper hardware enhances temperature control, airflow management, and hygiene across industries.

At Extruflex, we know that the right mounting system can make all the difference. That’s why we focus on creating solutions that are easy to install, built to last, and adaptable to a variety of spaces. Whether you're working in manufacturing, logistics, or food processing, our hardware is designed to provide reliable support where it matters most.

Our Mounting Hardware Solutions

Extruflex offers a range of mounting systems, each designed for specific environments and operational needs.

QuickMount Hardware System: The fast simple easy mounting system

For businesses needing a fast and straightforward installation, the QuickMount System is the ideal choice. Designed for rapid installation with minimal tools, it makes strip installation 75% faster than traditional mounting systems and strip replacement 90% faster.

Despite its ease of installation, the QuickMount maintains durability in moderate traffic conditions, offering a balance of convenience and performance.

The QuickMount system comes in two styles, each designed to meet different needs depending on the application and level of durability required:

QuickMount MD (Medium Duty)

- Ideal for lighter-duty applications where frequent strip curtain replacement or moderate foot and equipment traffic is expected.

- Designed for quick and easy installation, making it a great option for businesses that need a reliable yet flexible mounting system.

- Suitable for small to mid-sized doorways, walk-in coolers, and controlled-access areas in warehouses, retail spaces, and commercial kitchens.

QuickMount HD (Heavy Duty)

- Built for high-traffic and industrial environments that require a stronger, more robust mounting system.

- Provides greater load-bearing capacity and enhanced durability, ensuring stability even in large openings and areas with heavy forklift or machinery movement.

- Best suited for distribution centers, manufacturing plants, cold storage facilities, and loading docks where long-term performance is essential.

Both QuickMount MD and QuickMount HD offer tool-free strip replacement, allowing for minimal downtime and hassle-free maintenance, making them a practical and efficient choice for businesses that rely on flexible PVC strip curtains.

Twin Track System

Featuring a dual-track mechanism, it allows the repositioning of curtains to accommodate changing operational needs, enhancing workflow efficiency.

Industries such as manufacturing, logistics, and automotive benefit from its adaptability and ease of use. This system ensures seamless access to restricted areas while preserving environmental separation.

The Twin Track System is designed for businesses that need both flexibility and functionality in their strip curtain installations. With its dual-track mechanism, this system allows for smooth repositioning of curtains, making it ideal for areas where access and environmental separation must be balanced.

Key Features & Benefits

Unlike fixed strip curtain mounts, the Twin Track System allows curtains to slide open or closed as needed. This enhances workflow efficiency by providing on-demand access to workspaces, machinery, or storage areas.

Employees and equipment can easily pass through without interference, reducing downtime and enhancing safety. The ability to reposition the curtains quickly helps optimize movement in high-traffic areas.

Constructed from heavy-duty materials, the Twin Track System is built to withstand constant use in industrial and commercial environments while requiring minimal maintenance.

With its versatile functionality and smooth sliding mechanism, the Twin Track System is a practical, long-term solution for businesses that require both controlled environments and flexible access.

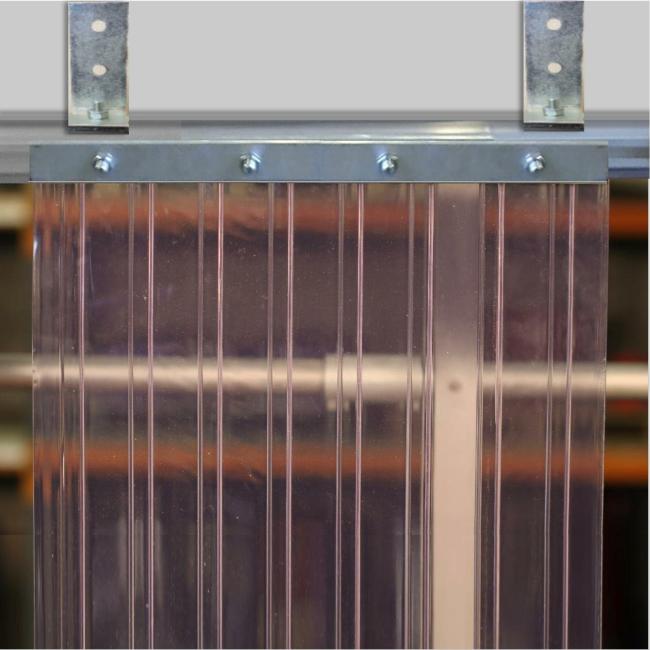

Bolt-On Galvanized Mounting Hardware

Designed for tough and demanding environments, the Bolt-On Galvanized Mounting Hardware is a heavy-duty solution. Constructed from corrosion-resistant materials, it withstands extreme conditions, including exposure to moisture, chemicals, and high-impact traffic.

Engineered for permanent installations, it offers maximum security and durability, making it suitable for industrial facilities, warehouses, and food processing plants. This system guarantees long-term performance without frequent adjustments or replacements.

The Bolt-On Galvanized Mounting Hardware is available in three formats, each designed to accommodate different installation needs and mounting surfaces. These options provide secure and long-lasting support for PVC strip curtains in a variety of settings.

1. Wall-Mount (Face-Mount)

- Also known as Face-Mount, this installation style is designed for mounting directly onto a vertical surface, such as a wall or door frame.

- Ideal for applications where there is limited overhead clearance or when the mounting surface is flush with the opening.

- Commonly used in walk-in freezers, loading docks, and warehouse doorways where a strong and stable attachment is required.

2. Under-Lintel Mount (Header Mount)

- Also referred to as Header Mount, this format is designed for mounting underneath a horizontal surface, like a doorway lintel or overhead beam.

- Provides a clean and space-efficient installation, making it ideal for areas where the top of the opening must remain unobstructed.

- Often used in cold storage rooms, food processing areas, and industrial spaces where maximizing vertical clearance is a priority.

3. Universal Mount

- A versatile option that combines the flexibility of both wall-mount and under-lintel mount configurations.

- Allows for installation on a variety of surfaces, making it the go-to choice for businesses that need adaptability in different environments.

- Ideal for multi-purpose applications where mounting conditions may vary, such as in warehouses, logistics centers, and high-traffic areas.

Each format of the Bolt-On Galvanized Mounting Hardware ensures a secure, durable, and easy-to-install solution, designed to withstand heavy use in demanding environments while supporting quick strip replacement for ongoing maintenance efficiency.

Choosing the right mounting hardware for your application

To ensure optimal performance, selecting the correct mounting hardware is essential. Several factors should be considered:

- Environment: Determine whether the hardware will be used indoors or outdoors, and consider exposure to moisture and temperature fluctuations.

- Traffic Levels: High-traffic areas may require quick-change systems that facilitate easy maintenance.

- Ease of Maintenance: Some systems offer tool-free strip replacement, which can reduce downtime and simplify upkeep.

- Durability: Long-term performance is crucial, especially in extreme conditions such as warehouses or food processing plants.

- Fixed vs. Sliding Systems: Fixed systems offer stability and are ideal for stationary barriers like cold storage. Sliding systems allow strip curtains to move along a track, making them suitable for high-access areas like warehouses.

How to ensure proper installation for maximum efficiency?

Proper installation plays a crucial role in ensuring that your PVC strip curtains provide the best performance. Consider these best practices:

Measure Precisely

Accurate measurements ensure correct strip overlap and coverage, preventing gaps that reduce efficiency.

Choose the Right Hardware

Matching the mounting hardware to the environment and traffic needs helps maintain long-term performance.

Secure Fixtures Firmly

Tighten screws and bolts properly to prevent loosening over time.

Perform Regular Maintenance

Periodic inspections help identify signs of wear, ensuring timely replacements and continued efficiency.

Why Extruflex mounting hardware?

Extruflex mounting hardware is trusted worldwide for its high-quality materials, durability, and performance-driven design. Here’s why.

High-Quality Materials

Manufactured with top-tier, corrosion-resistant components, Extruflex hardware offers long-lasting durability, even in harsh conditions such as moisture, chemicals, and temperature fluctuations.

Easy Installation & Maintenance

Designed for quick and simple installation, our mounting hardware reduces setup time and labor costs. Many systems require minimal tools and allow for hassle-free strip replacement, ensuring smooth operation with minimal downtime.

Versatility & Customization

From fixed to sliding mounting options, our solutions cater to a range of industry needs. Customizable configurations ensure optimal functionality for specific operational requirements.

Proven Reliability

With years of industry expertise and rigorous product testing, Extruflex hardware is designed to perform in high-traffic environments and extreme operational conditions, delivering consistent results businesses can rely on.

Get in touch with Extruflex

Explore our full range of mounting hardware solutions to find the perfect fit for your application. Whether you need a quick-install option or a heavy-duty, permanent solution, our team is ready to assist.

Contact us today for expert consultation and product recommendations. Visit our website to view product specifications, case studies, and installation guides.