Protect sensitive operations with anti-static PVC from Extruflex—formulated to dissipate charge and safeguard equipment in the most demanding environments.

Most people think of static electricity as a harmless zap from a doorknob or static cling in the laundry. But in high-tech or sterile environments, that tiny jolt can cause major disruptions.

Imagine a technician walking through a server room. As they move, friction builds an electrical charge. A single discharge can damage equipment, corrupt data, or contaminate sensitive materials—often before anyone notices.

Static is especially dangerous because it’s invisible and silent. There’s no warning. It builds up on surfaces and people, then releases in a flash.

In sectors like electronics, pharmaceuticals, and logistics, that flash can mean thousands in downtime or lost goods. In environments with flammable substances, it can even trigger explosions.

So how do you stay ahead of static risk before it disrupts your operations? Anti-static vinyl offers a straightforward solution—designed to prevent problems before they start.

How Anti-Static Vinyl Works

While the concept is straightforward, manufacturing anti-static vinyl requires precise formulation. It starts with standard PVC, a material known for its clarity, durability, and flexibility. These qualities make it a go-to for industrial strip curtains, partitions, and swing doors.

But there’s a catch:

PVC is naturally non-conductive. That’s great for insulation—but not so great when it comes to controlling static.

Since PVC doesn’t conduct electricity, it can act like a sponge for static charge. As people, equipment, or materials interact with it, charge builds up on the surface. And without a way to release that charge gradually and safely, the material becomes a potential flashpoint—especially in environments filled with sensitive electronics or volatile compounds.

Anti-static vinyl addresses this by tweaking the formula.

During production, specialised additives are blended into the vinyl. These additives reduce the surface resistivity of the material, giving static charges a controlled path to dissipate. Not instantly, and not dangerously—just slowly and safely enough to prevent build-up.

Here’s how it breaks down in terms of material properties:

- Insulative materials (like untreated PVC) have a surface resistivity above 10¹² ohms per square—they hold static.

- Conductive materials, often used for grounding, fall below 10⁵ ohms per square—they release charge instantly.

- Static dissipative materials, including anti-static vinyl, land between 10⁵ and 10¹¹ ohms per square—this is the key to managing static without creating other electrical risks.

That balance is what makes anti-static vinyl effective. It provides just enough conductivity to allow charges to dissipate, but not so much that it interferes with surrounding electronics or safety systems.

With high-quality options like Extruflex anti-static range, those protective properties are built into the vinyl itself—not sprayed on afterward. That means the vinyl continues to perform even after months or years of use. No flaking, no fading, no surprises.

Built to Withstand the Real World

Not all anti-static materials are created equal—and that matters when lives, equipment, or production quality are on the line. Here’s how anti-static vinyl from Extruflex stands apart:

Engineered for Durability

Unlike surface-coated options, Extruflex anti-static vinyl is fully integrated. The static-dissipative additives are blended throughout the vinyl during manufacturing. That means:

- No coatings to wear off

- No drop in performance after cleaning or abrasion

- Consistent protection, inside and out

Made for Daily Use

This material is built to survive real industrial environments. Whether it’s mounted in a high-traffic doorway or partitioning off a cleanroom:

- It holds up under heavy foot and vehicle traffic

- It resists UV rays and chemical cleaners

- It stays flexible in fluctuating temperatures

Performs Beyond Static Control

While static mitigation is the primary function, you get added benefits:

- Dust and particle control

- Thermal separation for climate-sensitive zones

- Noise reduction in loud facilities

- Clear visibility through transparent panels

Why It’s Essential Across Industries

Static control isn’t just a tech issue. It’s a quality issue, a safety issue, and in many cases, a regulatory issue. Here’s how anti-static vinyl quietly plays a critical role across key sectors:

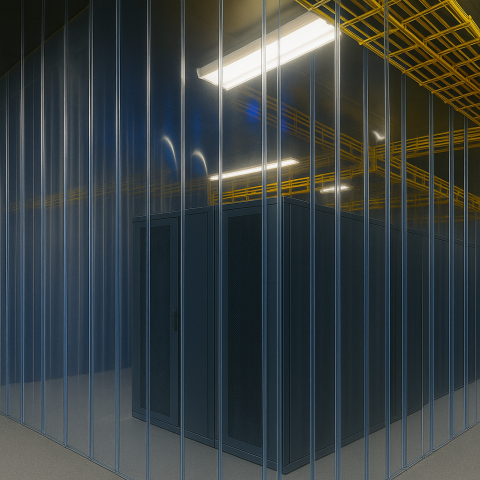

Electronics & Data Centers

In environments filled with servers, circuit boards, and sensors, even a tiny static discharge can corrupt data or permanently damage components. Anti-static vinyl creates neutral zones—through strip curtains or partition walls—that help shield delicate systems from unseen electrical threats.

Pharmaceuticals & Cleanrooms

Clean environments rely on static control to keep airborne particles from settling on sensitive surfaces. Static attracts dust, microbes, and fibers—none of which belong in sterile production lines. Anti-static vinyl acts like a passive air filter, reducing contamination without interrupting workflow.

Printing, Packaging & Labels

Ever had sheets stick together, jam machinery, or misfeed at the worst time? That’s static. In high-speed production environments, anti-static barriers help ensure smoother material handling—preventing misalignments and wasted runs.

Hazardous or Flammable Environments

In facilities that handle fine powders, vapors, or gases, one spark can trigger catastrophe. Anti-static vinyl helps lower the risk by preventing those charges from building up in the first place—turning a volatile zone into a controlled space.

Wherever Traffic Meets Risk

Loading docks, warehouse doorways, production zones—these are high-movement areas where people, carts, and forklifts constantly pass through. Anti-static vinyl strips don’t just separate spaces; they stabilize the environment, making every crossing safer and cleaner.

Why It Matters More Than Ever

Today’s facilities operate with razor-thin margins for error.

A single ESD incident can corrupt data, shut down systems, or compromise sterile production—costing far more than just time.

Anti-static vinyl helps prevent those outcomes. It doesn’t just protect the hardware. It protects your process, your product quality, your team, your compliance—and your reputation.

And it does all this without ongoing maintenance, reapplication, or manual oversight. Once installed, the vinyl continuously disperses static without manual intervention.

Ready to Strengthen Your Static Protection?

At Extruflex, we don’t just manufacture flexible PVC—we engineer reliable solutions for high-performance environments. Our anti-static vinyl is designed to quietly protect your operations from the risks you can’t see—safeguarding your equipment, your products, and your people.

Whether you're outfitting a cleanroom, upgrading a data center, or reinforcing safety in high-traffic zones, our anti-static PVC delivers lasting performance where it matters most.

Let’s help you reduce risk, improve compliance, and keep your facility running smoothly.

Explore our clear antistatic vinyl solutions for full specifications and application details.

Or contact our team to discuss the best solution for your environment.