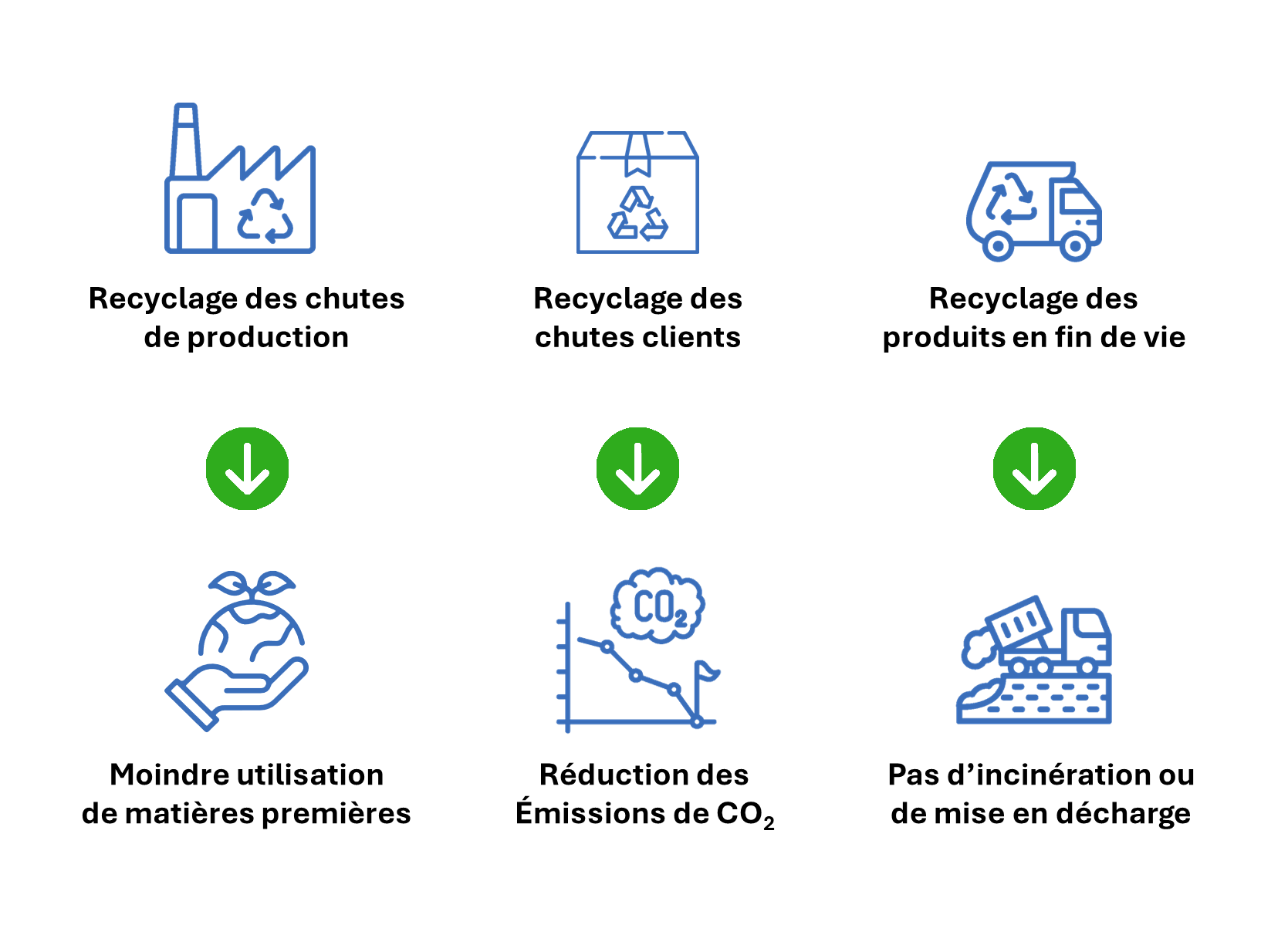

Extruflex is at the forefront of recycling and is implementing a proactive and ambitious recycling policy. We are implementing a recycling policy at three levels:

/ Recycling our internal production offcuts

The production of flexible vinyl reels generates production off-cuts during line start-up and set-up operations, and when cutting to size (production “widths”). These offcuts are systematically reused internally in the manufacture of our products.

/ Recycling our customers' cutting scraps

The manufacture of doors, partitions or other parts by our customers can generate off-cuts. We offer to take them back and reuse them in the manufacture of new products.

/ Recycling of end-of-life products

Extruflex is launching a program for the recovery and reuse of end-of-life products, in collaboration with its customers and distributors. This involves recovering products after use, cleaning and degreasing them, then reusing them to manufacture new products, thereby establishing a genuine circular economy.

Recycling is fun!

Recycling raw materials has the following benefits for the environment:

- It reduces the consumption of virgin raw materials and therefore the extraction and use of resources from petrochemicals,

- It therefore reduces CO2 emissions (scope 3),

- It avoids the landfilling or incineration of end-of-life products.

The process of recycling doors or partitions is simple and easy to implement:

- Due to their simplicity, flexible vinyl doors and partitions are easy to disassemble, uninstall and transport;

- Soft vinyl is a single material and does not require any complex separation of different layers of materials.

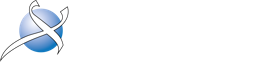

The recyclability of recovered products depends on their condition.

It is essential that the materials are returned to us:

- Sorted: returns must consist only of flexible PVC from strips or panels;

- Free of foreign bodies and clean: returns must be free of any metal parts (hanging plates, rivets, iron wires, etc.), stones, adhesives and wires of all kinds.

- Extruflex products: to protect our employees from potentially toxic additives and guarantee you a quality product, we only take back products manufactured by Extruflex.

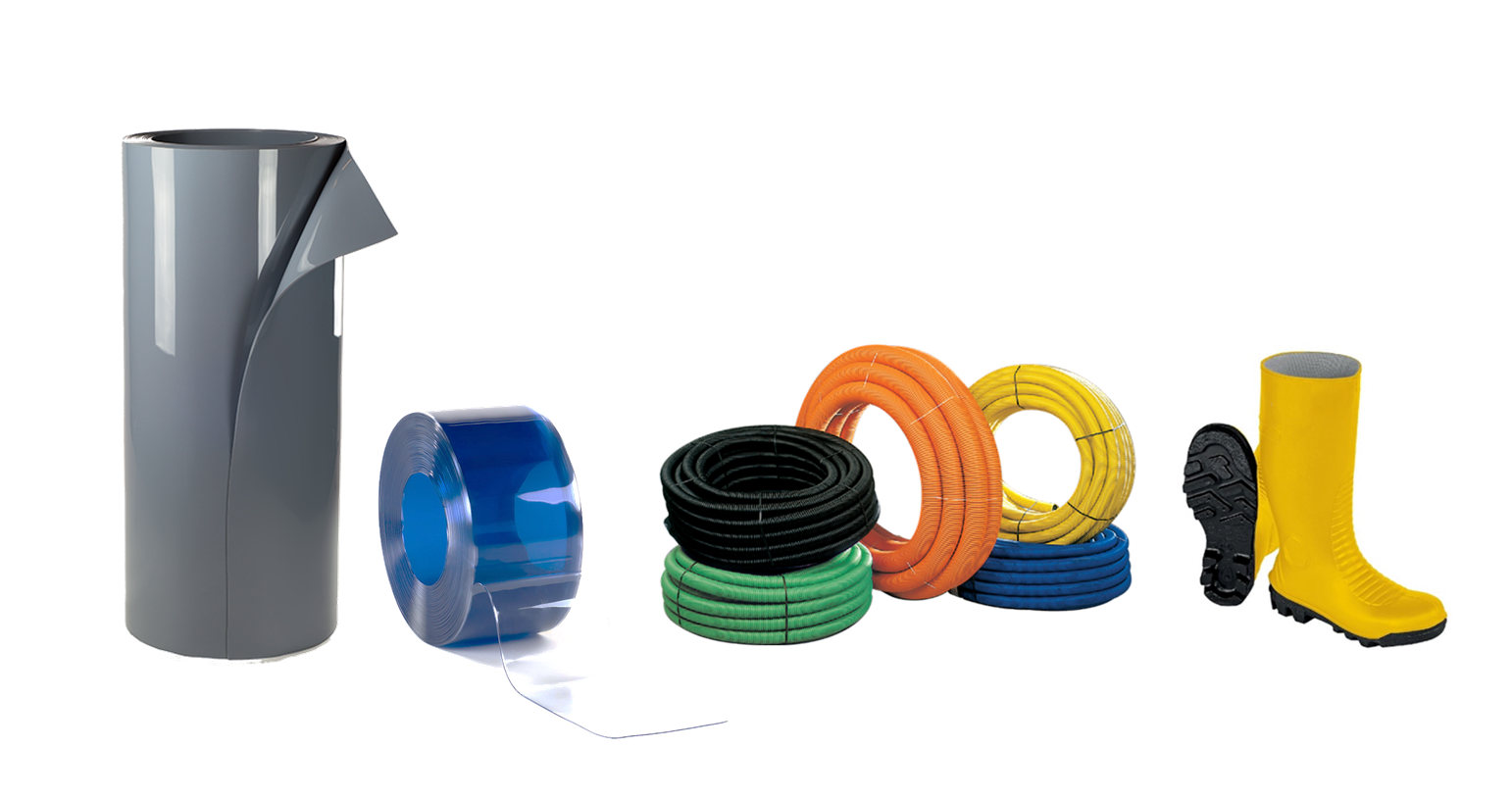

Depending on the quality of the returns, the products we recover may be reused :

- if they are of good quality, in new Extruflex strips or panels, transparent or opaque,

- if they are of average quality, in Extruflex products with less stringent quality requirements (black floor protection mats, etc.).

- if they are of poor quality and we cannot reuse them, we undertake to pass them on to partners who can use them in less demanding applications in terms of quality (cabling, shoe soles, etc.).

Our commitment:

Your returned products will have a second life, either in the manufacture of new products in our factories, or in the manufacture of other products by partners;

As a result, your used products will neither end up in landfills nor incinerated.

Through the quality of the sorting carried out upstream of the recovery of products, you have to play an important role in the success of the establishment of a real circular economy!

Our recycling programs: