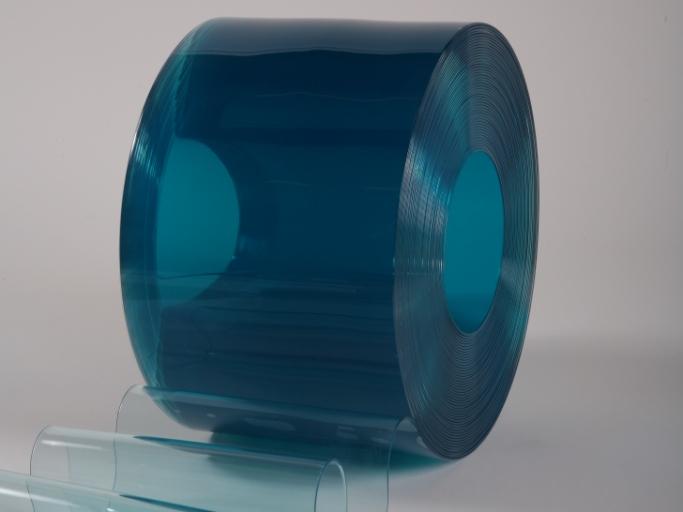

Find out how our polar PVC strips maintain flexibility in extreme cold, providing reliable insulation and improved efficiency.

Polar PVC strips play a critical role in maintaining temperature control in environments like cold storage facilities, refrigerated transport, and walk-in freezers. However, traditional PVC curtains often become rigid and brittle in extreme cold, leading to compromised insulation, higher energy costs, and potential breakage.

At Extruflex, we’ve taken on this challenge with a revolutionary approach. Our polar PVC strips are engineered to deliver unmatched flexibility and reliability, even in the harshest sub-zero conditions.

How do we achieve this remarkable feat?

Let us take you behind the scenes to reveal the science, innovation, and dedication that make our polar PVC a market leader.

Tailored formulation for Extruflex polar PVC strips

Our advanced polar PVC strips formulation is the foundation of our freezer curtains’ exceptional performance. Designed specifically for sub-zero conditions, it provides:

- Unmatched Flexibility: Leveraging innovative plasticisers, this formulation ensures our PVC remains pliable and effective, even at temperatures as low as -40°C (-40°F).

- Rigorous Reliability: Each batch undergoes comprehensive testing to maintain a balance of flexibility and durability, guaranteeing performance in the most demanding conditions.

- Uniform Excellence: Our precision-engineered blend ensures consistent quality, making every strip as reliable as the last

This cutting-edge formulation creates a high-performance PVC that bends, flexes, and endures without breaking, extending both product lifespan and reliability.

Optimised manufacturing process

To complement our tailored formulation, our manufacturing process ensures our polar PVC strips deliver flawless performance:

- State-of-the-Art Extrusion Technology: Advanced equipment shapes and forms PVC with precision, guaranteeing consistent thickness, flexibility, and durability.

- Controlled Cooling and Curing: Rigorous monitoring locks in flexibility and structural integrity, ensuring the material retains its properties even in sub-zero conditions.

- Stringent Quality Assurance: Detailed inspections at every stage confirm that our PVC meet the highest standards for safety, durability, and performance.

This synergy between formulation and manufacturing results in freezer curtains that businesses worldwide can trust for consistent performance.

Energy efficiency benefits of polar PVC

One of the standout advantages of Extruflex polar PVC strips is their exceptional contribution to energy efficiency. By forming a dependable barrier that maintains a tight seal, our freezer curtains:

- Minimise Temperature Loss: Stabilise interior temperatures and reduce strain on commercial refrigeration systems by preventing cold air from escaping.

- Lower Energy Consumption: Efficient insulation translates to significant energy savings, allowing businesses to operate more sustainably and cost-effectively.

- Enhance Operational Efficiency: With less temperature fluctuation, refrigeration systems experience reduced wear and tear, extending their lifespan and lowering maintenance costs.

- Reduce Environmental Impact: Help businesses lower their carbon footprint and contribute to global sustainability initiatives by cutting down energy usage.

- Optimise Product Quality: Help preserve the integrity and freshness of perishable goods, reducing spoilage and waste by maintaining consistent temperatures.

These comprehensive benefits not only bolster operational profitability but also align with long-term environmental and business goals.

Real-world applications of polar PVC strips

Our polar PVC strips are relied upon across industries, offering tailored solutions for specific needs:

- Cold Storage Facilities: Superior insulation keeps cold air inside, reducing energy demand and maintaining optimal storage conditions.

- Food Processing Plants: Hygienic and durable, our PVC strips handle high traffic and rigorous cleaning while ensuring precise temperature control.

- Supermarkets and Retail: Transparent, flexible strips enhance energy efficiency and customer convenience while preserving perishable goods.

- Logistics and Transport: Protecting perishable goods during transit, our PVC strips prevent temperature fluctuations and ensure product integrity.

- Hospitality and Catering: Reliable and durable, they maintain food safety and efficiency for hotels, restaurants, and catering operations.

Why Choose Extruflex?

Extruflex offers unparalleled expertise in PVC innovation, making us the preferred choice for temperature-controlled solutions:

- Superior Quality: Rigorous checks ensure long-lasting performance.

- Innovative Technology: We continually refine our manufacturing processes to deliver cutting-edge products.

- Custom Solutions: Tailored options meet the unique needs of diverse industries.

- Global Presence: Our solutions are trusted by businesses worldwide.

- Decades of Experience: Our 60+ years of expertise ensure that every product reflects industry-leading knowledge and innovation.

A Commitment to Excellence

At Extruflex, we don’t just manufacture PVC; we redefine its capabilities. Our dedication to quality, innovation, and sustainability ensures that our polar PVC strips remain the industry benchmark. Whether you’re looking to improve energy efficiency, maintain product integrity, or enhance operational performance, Extruflex has the solutions you need.

Ready to transform your operations?

Contact us today and experience the Extruflex difference.