Discover why Anti-Insect PVC Strips are a cleaner, smarter, chemical-free alternative to traditional pest control in industrial and food-safe settings.

Every open doorway in a facility is an open invitation—not just to goods and workers, but to flying insects that compromise hygiene, regulatory compliance, and operational integrity. In food plants, warehouses, and processing environments, a single fly can mean a failed audit or a ruined batch.

While traditional pest control methods fight fire with fire—using chemicals, noise, or electricity, there’s a quieter, cleaner alternative gaining ground: Anti-Insect Yellow PVC Strip Curtains.

Subtly infused with Citronella and precision-engineered to disrupt insect attraction patterns, these strips create an invisible barrier that works all day, every day—without sprays, traps, or power. Just smart design, passive protection, and peace of mind.

How Anti-Insect PVC strips work

Anti-Insect PVC strip curtains are more than just a visual deterrent—they’re a scientifically informed, low-maintenance solution designed to keep flying pests out without compromising your operations or safety protocols.

1. Citronella-infused vinyl

Each strip is embedded with Citronella, a natural essential oil extracted from lemongrass.

Recognised for its insect-repelling properties, citronella effectively discourages flies, mosquitoes, and other airborne pests—without relying on synthetic chemicals or airborne sprays. The scent is subtle to humans but disruptive to insects, making it ideal for food production, packaging, and pharmaceutical environments. Citronella is considered safe for humans by the World Health Organization and the FDA. It is used worldwide as a natural alternative for pest control.

2. Insect-opaque Yellow Tint

The strips' distinct yellow pigment plays a critical role in pest prevention.

Research shows that most flying insects have limited sensitivity to yellow light wavelengths. This means they struggle to see through the curtain and are less likely to detect movement, light, or potential food sources beyond it.

Without visual cues, there’s no incentive for insects to come to the doorway, or land on the curtain.

3. Continuous, passive protection

Unlike sprays, traps, or electrical deterrents that require monitoring, refills, or maintenance, these PVC strips work passively—around the clock.

Once installed, they create a durable, physical and sensory barrier that operates 24/7 without interruption.

4. Perfect for chemical-free zones

Because they don’t emit volatile compounds (VOCs) or require active intervention, Anti-Insect PVC strips are perfectly suited for hygiene-critical environments where traditional chemical treatments are prohibited. From cold chain logistics to clean rooms and open-door loading bays, they help facilities maintain high standards without compromise.

Whether you're safeguarding food safety, maintaining sterile conditions, or protecting production lines, these anti-insect strips provide quiet, constant protection. It’s pest control without complexity—built for the real-world demands of modern industry.

The downsides of traditional pest control

Conventional pest control methods may be familiar, but they often fall short in modern industrial environments.

From chemical exposure to constant upkeep, these short-term fixes demand time, resources, and attention—without delivering continuous protection. In facilities where compliance and cleanliness are non-negotiable, it’s clear: a smarter, passive solution is needed.

Sprays and foggers

Chemical repellents require constant reapplication and introduce active substances into sensitive workspaces—raising concerns in food-safe or pharmaceutical areas.

Overuse can lead to chemical residue on surfaces, regulatory complications, and increased risk of contamination. In short, they're temporary solutions to a persistent problem.

Electric zappers

While zappers may reduce insect numbers, they’re noisy, energy-intensive, and often unsuitable for clean environments. Insect debris can scatter, posing a contamination risk near packaging lines, prep zones, and production equipment.

The visual and audible disruption alone can be enough to disqualify them in hygiene-controlled settings.

Air curtains

Air curtains create a stream of forced air intended to block insects at entry points—but their performance is inconsistent. They’re costly to install, require electricity to run continuously, and are vulnerable to environmental factors like wind or temperature fluctuations.

If the conditions aren’t right, neither is the protection.

Screens and solid doors

Physical barriers like mesh screens or heavy doors can keep pests out—but they’re impractical in high-traffic areas.

In facilities where forklifts, carts, or personnel need continuous access, these barriers often get left open or bypassed, undermining their purpose and reducing efficiency.

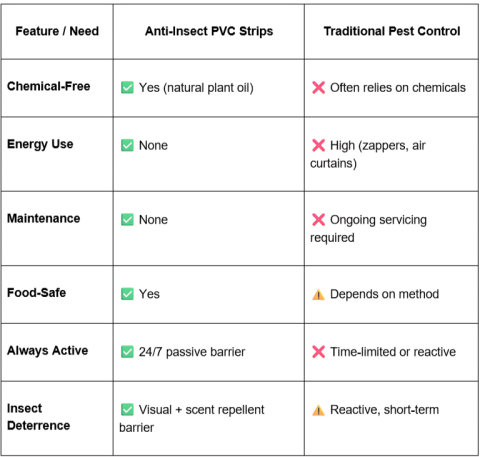

Anti-insect PVC strips vs. traditional pest control

In fast-paced environments where downtime isn’t an option, choosing the right pest control method goes beyond effectiveness—it’s about efficiency, sustainability, and safety.

The table below highlights the key differences between anti-insect yellow PVC strips and conventional pest control solutions:

Unlike conventional systems that consume energy require frequent intervention, or introduce chemicals into sensitive environments, Anti-Insect PVC strips operate silently and continuously.

With zero operating costs, zero maintenance, and round-the-clock effectiveness, they offer a set-it-and-forget-it solution tailored for compliance-driven industries.

When performance, sustainability, and simplicity matter, the choice is clear.

Where it makes a difference

Anti-Insect Yellow PVC Strip Curtains aren’t just an alternative to traditional pest control—they’re a purpose-built solution for the environments where it matters most. Designed to perform without chemicals, power, or maintenance, these strips excel in high-traffic, hygiene-sensitive, and compliance-driven settings.

Ideal applications include:

- Food production & packaging areas

Maintain HACCP compliance while keeping pests out—without introducing contaminants or chemical residues. - Food service & restaurants

Protect back-of-house and delivery access points with a discreet, effective barrier that doesn’t disrupt workflow. - Warehouse dock doors & logistics hubs

Prevent flying insects from entering large bays where constant movement makes traditional barriers impractical. - Waste zones near cleanrooms or processing lines

Shield clean zones from contamination by isolating adjacent waste or disposal areas. - Agricultural, dairy & livestock facilities

Provide year-round pest deterrence in facilities that require natural, chemical-free control methods. - Retail stores, bakeries & beverage plants

Safeguard customer-facing and production areas with a professional, low-profile solution that works silently behind the scenes.

In locations where doors are open frequently or remain partially ajar, Anti-Insect PVC strips form a reliable barrier that’s always active—blocking insects at the threshold before they become a problem.

From food safety to facility efficiency, these curtains deliver where conventional methods can’t.

Smarter protection starts at the door

When it comes to insect control, prevention is not only more effective—it’s more sustainable.

Anti-Insect Yellow PVC strip curtains offer a chemical-free, energy-efficient solution that works 24/7. Infused with natural citronella and engineered with a yellow tint that flies can’t see through, these curtains create a clean, passive barrier that keeps pests out before they become a problem.

Ready to make the switch to smarter pest control?